In the competitive and demanding world of powersports aftermarket parts—covering motorcycles, ATVs, UTVs, and more—reliability and performance are critical. Riders expect upgrades, not compromises. To meet those expectations and ensure safety, a robust product testing protocol is essential. Here are five best practices to guide the development of effective and relevant testing processes.

1. Start with Real-World Use Cases

Before setting up a lab test, define the actual usage environment. Will the part be used in off-road, high-speed, or all-weather conditions? Consider:

- Terrain impact (mud, gravel, jumps)

- Vibration and mechanical shock

- Temperature extremes

- Water and dust exposure

Understanding these variables ensures your testing simulates real-world abuse, not just ideal conditions. Testing a handlebar clamp for static strength alone is meaningless if it fails under repeated trail impacts.

2. Benchmark Against OEM and Market Standards

Use OEM specifications and competitor products as your baseline. Analyze their strengths and weaknesses through reverse engineering or side-by-side performance testing. This allows you to:

- Set realistic but competitive performance goals

- Validate product improvements

- Ensure compatibility with existing platforms

Don’t just aim to “match” OEM—design your protocol to exceed it where riders demand better durability or functionality.

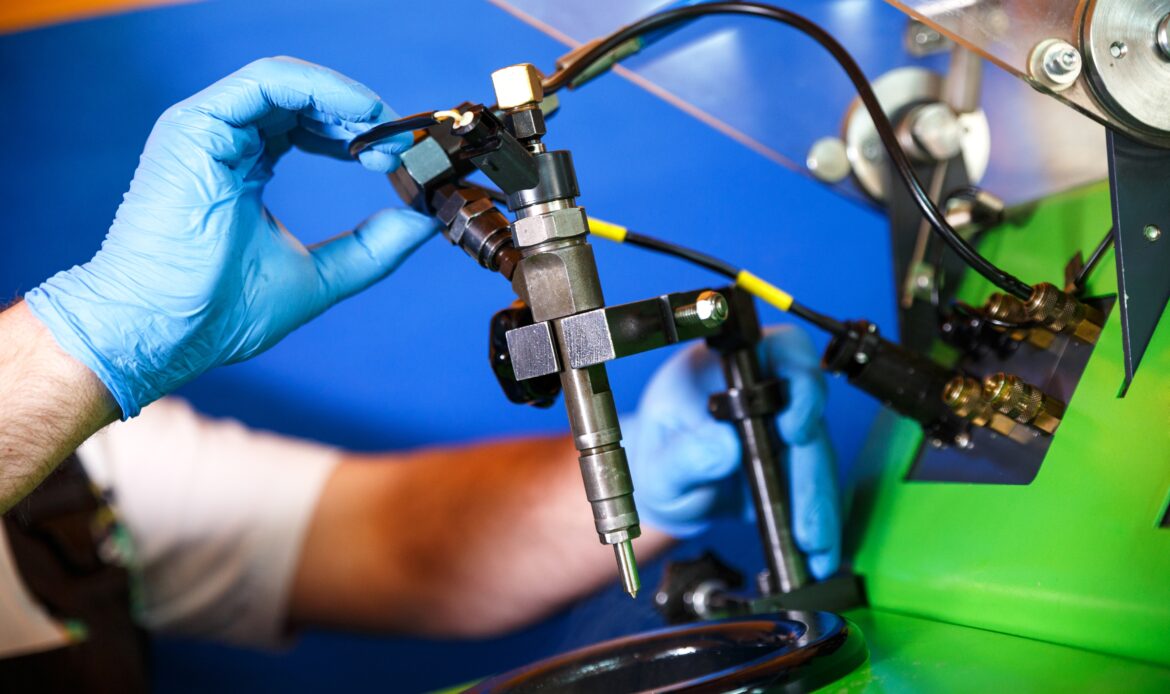

3. Use a Mix of Lab and Field Testing

Lab testing provides repeatable, controlled results. Field testing reveals how a part behaves under unpredictable and cumulative stress. A well-rounded protocol includes:

- Fatigue testing (cyclic loading)

- Torque and tensile strength testing

- Corrosion resistance (salt spray, humidity)

- On-vehicle field testing by experienced riders

Combine quantitative data from the lab with qualitative rider feedback to cover both performance metrics and user perception.

4. Document Everything with Clear Criteria

Define pass/fail conditions before testing begins. Examples might include:

- “No visible cracking after 100,000 vibration cycles”

- “Corrosion not exceeding 5% surface area after 72 hours in salt spray”

- “Torque retention above 90% after 10 assembly/disassembly cycles”

Keep detailed test logs, photos, and results. Documentation ensures repeatability, supports quality assurance, and helps in case of warranty or liability disputes.

5. Plan for Continuous Improvement

Testing shouldn’t be a one-time event. Use test results to improve your designs and adjust future testing protocols as materials, riding styles, or regulations evolve. Consider:

- Building a feedback loop from customer returns and warranty claims

- Updating test methods as new industry standards emerge (e.g., ISO, SAE)

- Tracking changes across product revisions to maintain consistency

Product testing is not just about validation—it's a key part of product evolution and brand trust.

Conclusion

In the powersports aftermarket industry, where performance and safety are non-negotiable, testing protocols must be thorough, realistic, and well-documented. By grounding tests in real-world usage, benchmarking wisely, combining lab and field data, setting clear standards, and committing to continuous improvement, you can ensure your parts not only fit—but thrive—on the toughest rides.