Why Trading & Engineering Partners Add Real Value in the Powersports Aftermarket Industry

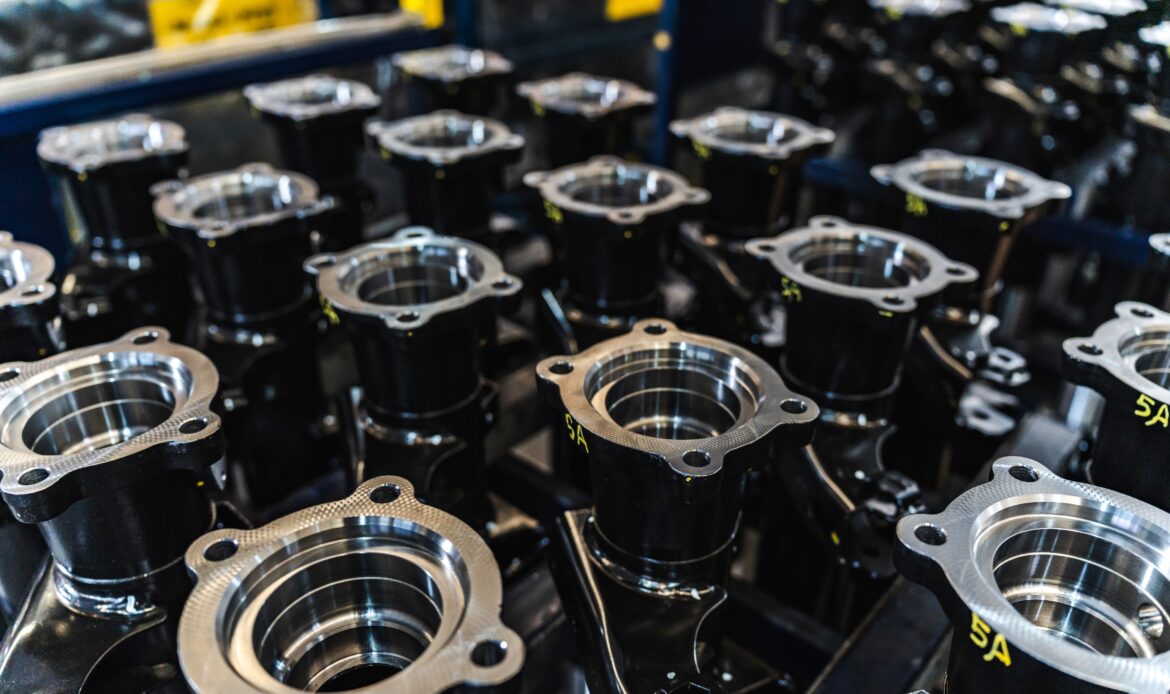

For many brands in the powersports aftermarket industry, the idea of working directly with a factory sounds appealing. It promises lower costs, faster communication, and tighter control—at least in theory. In reality, dealing directly with manufacturers can introduce unexpected challenges that impact product quality, delivery, and even brand reputation.

Here are some of the most common issues companies face when working directly with factories—and how a trusted trading and engineering partner like us helps avoid them.

1. Miscommunication on Technical Requirements

The problem: Many factories are production-driven, not design-driven. If product specifications are unclear—or if the factory misunderstands functional expectations—the result is often a product that “looks right” but performs poorly.

Our solution: As a product engineering-focused trading partner, we act as a translator between your design intent and the factory’s production language. We create clear, detailed tech packs, perform pre-production reviews, and verify that every critical spec is understood and executable.

2. Lack of Proactive Quality Control

The problem: Some factories rely on reactive quality control—fixing issues only after they appear. Without structured QA procedures, defects may go unnoticed until it’s too late.

Our solution: We implement a proactive quality control process, including:

- Incoming material checks

- In-line production audits

- Final inspections based on agreed protocols

This helps catch issues early and reduces the risk of costly returns or field failures.

3. Limited Engineering Support

The problem: When developing custom or upgraded aftermarket parts, factories may not offer the engineering support needed for design validation, testing, or performance improvement.

Our solution: We provide in-house engineering support, including:

- DFM (Design for Manufacturing) guidance

- Performance testing protocols

- Continuous improvement based on rider feedback and warranty data

We bridge the gap between design innovation and factory feasibility.

4. Language and Cultural Barriers

The problem: Communication gaps, especially with offshore factories, can lead to misaligned expectations, delays, or unintended cost changes. Cultural differences may also impact negotiation or problem-solving styles.

Our solution: With bilingual staff experienced in manufacturing and powersports, we ensure nothing gets lost in translation. We manage communication clearly and efficiently, saving you time and frustration.

5. Risk of Over-Reliance on a Single Source

The problem: Working directly with one factory often means putting all your eggs in one basket. If they raise prices, delay delivery, or shift priorities, your supply chain suffers.

Our solution: We maintain a vetted network of reliable factories. This allows us to recommend the right fit for your product—and offer alternatives when needed to ensure flexibility and supply chain security.

Final Thoughts

Working with factories directly may seem efficient, but the hidden risks can cost more than they save. As a trading and engineering partner in the powersports aftermarket industry, we provide the technical oversight, communication clarity, and quality assurance you need—so your brand can focus on growth, not fire-fighting.