Our Solutions

Our extensive network of manufacturing partners in Taiwan and China provide our client partners with access to a multitude of manufacturing solutions such as CNC, die-casting, forging, laser cutting, stamping, injection molding, electronics, lighting, and wire harnesses, as well as prototyping, particularly for the Powersports Industry.

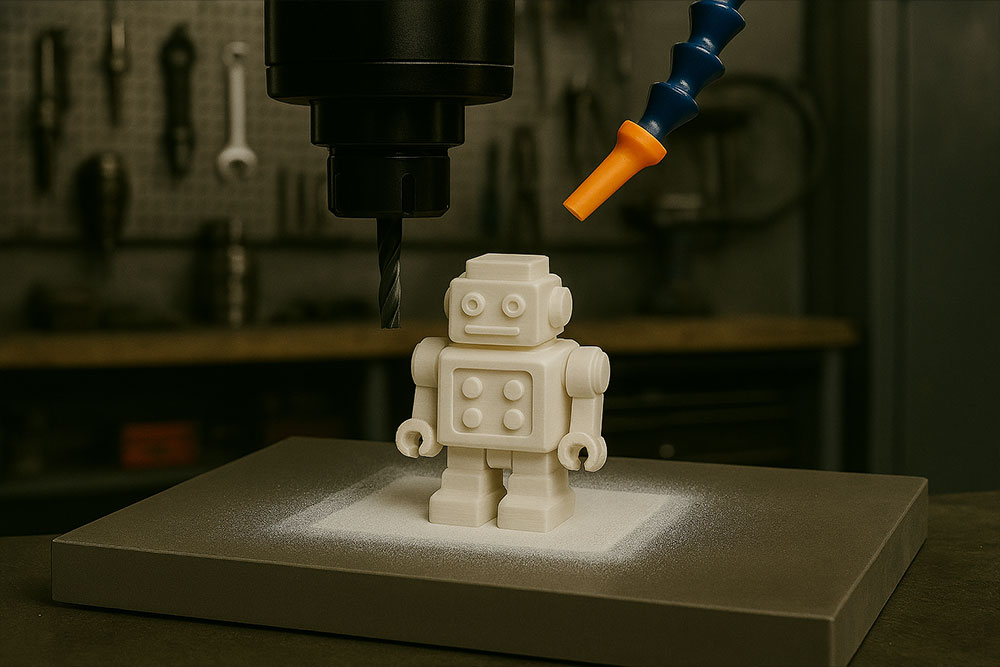

CNC

Application: Custom accessories, brackets, grips, footpegs, levers, wheels and hubs, chassis and suspension components, prototyping.

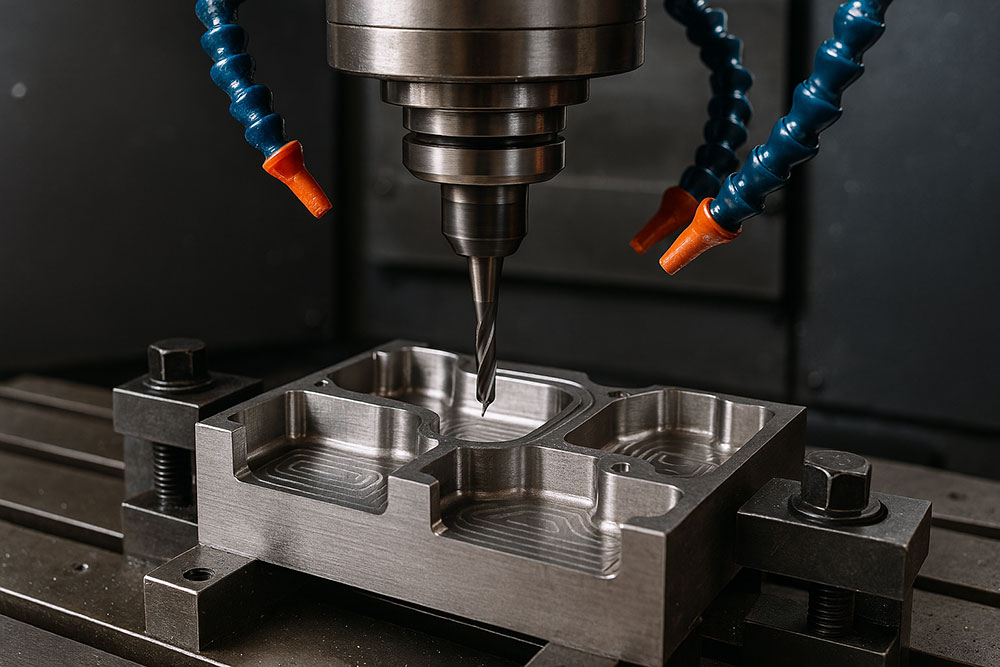

Die-Casting

Application: Engine components, cylinder head, cylinder block, crank case and housing, intake manifolds, brackets.

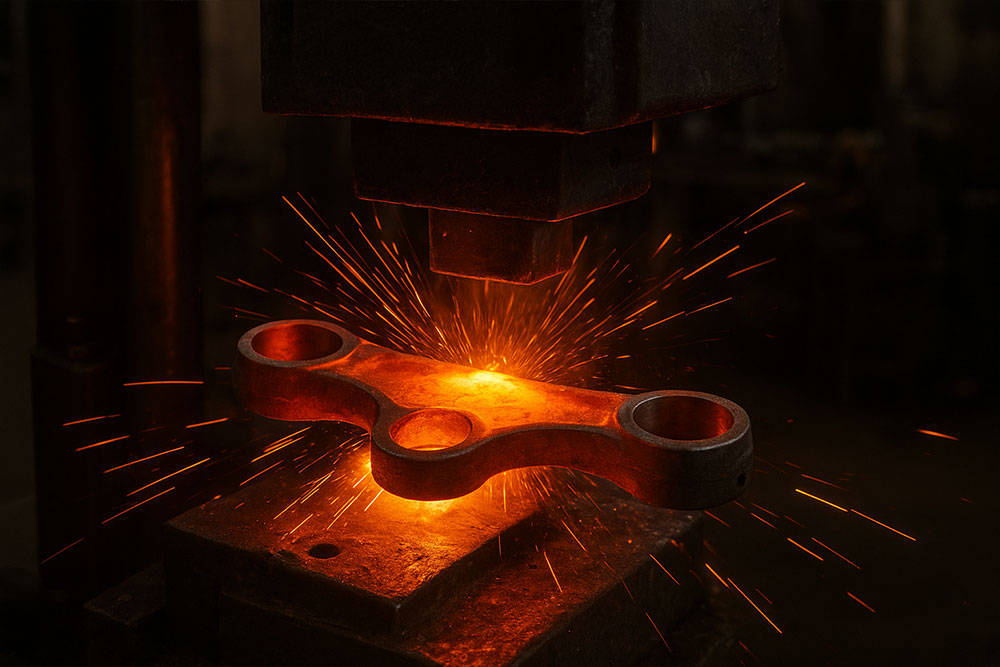

Forging

Application: Engine components, pistons, connecting rods, crankshafts, camshafts, chassis components, suspension components, wheels and hubs, custom accessories.

Laser Cutting

Application: Metal parts, brackets, frames, customized panels, custom accessories, prototyping.

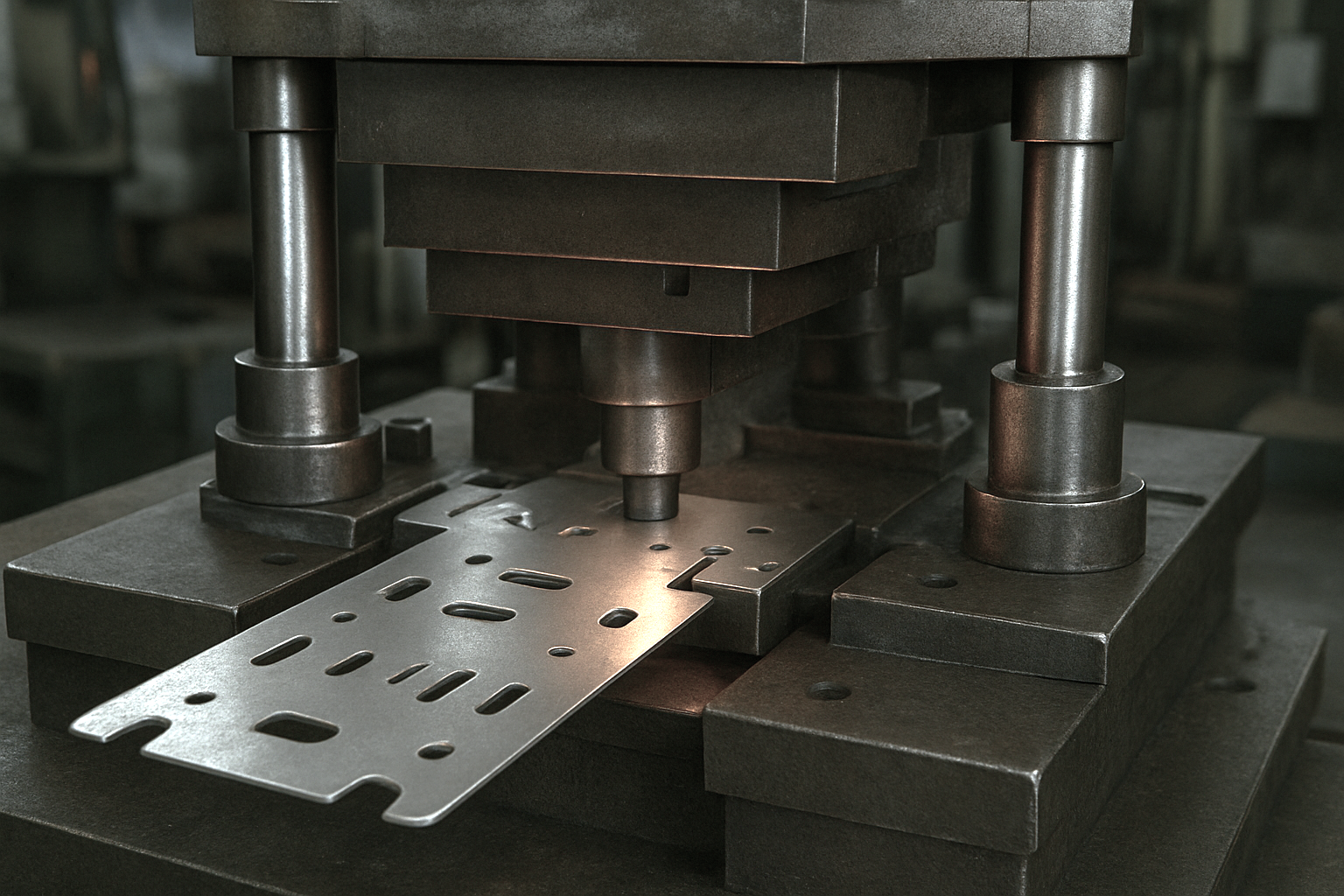

Stamping

Application: Engine covers, oil pans, brackets, frames, fenders, fuel tanks, body panels, custom accessories and trim.

Injection Molding

Application for Plastic Injection Molding: Exterior trim, fenders, grilles, housing, body panels, fairings, vehicle interior components, custom accessories, lighting components.

Application for Rubber Injection Molding: O-ring, grommets, seals, gaskets, bushing, grips, pegs, vibration-dampening components.

Electronics, Lighting, & Wire Harnesses

Prototyping