Our Services

In synergy with our solutions, our services are tailored to your needs for an effective partner to manage and execute overseas product development and manufacturing, bridging the gap between product design and the manufacturing process, thereby reducing time to market for your unique product. Our dedicated team consisting of customer service account executives and highly proficient engineers possess extensive experience in product development, quality assurance, and manufacturing specifically for clients in the Powersports Industry, and particularly for Motorcycles and UTV Parts & Accessories.

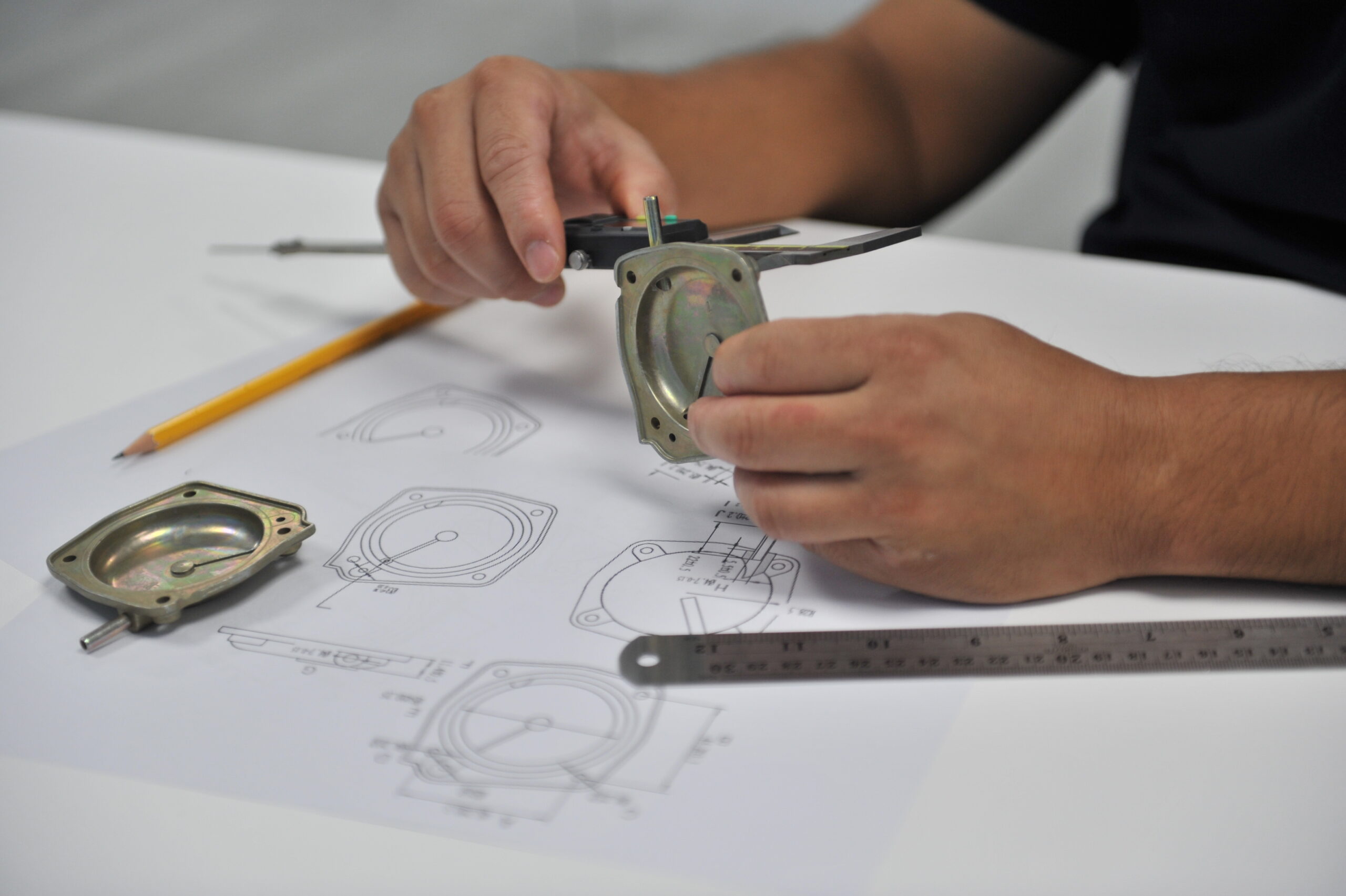

ODM Product Development & Engineering

Designing a product without taking into consideration the realistic parameters of material application and manufacturing process can often result in product designs that are not feasible for cost effective production, thereby preventing a product development project from moving forward. This obstacle can cause severe delays in time to market for a new product, as well as adding significant, unnecessary overrun of costs in time and money to the product development process.

Our dedicated team consisting of customer service account executives and highly proficient engineers possess extensive experience in product development, and will work with our clients efficiently and effectively to optimize the product design for cost-effective production feasibility through the following process:

01

Product Requirements Identification

We work with our clients to identify product requirements, such as performance ratings and safety standards to meet the demands of consumers, actual usage environments, and product longevity, and correspondingly identify the suitable material specifications, tolerances, and manufacturing process to meet those requirements.

02

Manufacturer Selection

We then select a suitable manufacturer capable of executing the production of the design which meets the above requirements and parameters.

03

Design Optimization

Combining technical feedback from the manufacturer with engineering solutions proposed by our team, we help our clients optimize the design for cost-effective production, while satisfying both product specifications and manufacturing requirements.

04

Prototype Validation

If tooling is required for production, our team can work with the client and the selected manufacturer to produce a functioning prototype sample to validate the design prior to investing in tooling development. This worthwhile investment will avoid unnecessary tooling modification costs and the associated delays.

05

Track and Monitor

During the production process, our team will continue to manage the production schedule and delivery timeline, track and monitor manufacturing progress, trouble-shoot and resolve any issues that may cause potential delays to maintain momentum, and through our methodical sample approval process, ensure that the critical product specifications and requirements are correctly and accurately executed by the manufacturer.

Product Sourcing, Private Branding, & Packaging

Sourcing a readily available product for private branding, applying your valuable brand onto the product and presented in an attractive private branded packaging, is an effective way to quickly expand your product offering. Opportunities for further differentiation and uniqueness can also be explored by implementing subtle modifications to a readily available product, to further optimize fitment and function. However, there are certain risks involved in product sourcing for private branding, such as manufacturing quality issues, and incorrect execution of private branding elements on the product and packaging, which may result in adverse effects of tarnishing your brand value and reputation. Our product sourcing service is designed to mitigate those potential risks, and to ensure correct execution of your private branding requirements.

Our dedicated team consisting of customer service account executives and highly proficient engineers will work with our clients efficiently and effectively to source a product for private branding, and to ensure that the private branding and quality requirements are executed correctly on the product as well as on the packaging through the following process:

01

Product Requirements Identification

We work with our clients to identify product requirements, such as performance ratings and safety standards to meet the demands of consumers, actual usage environments, and product longevity, and correspondingly identify the suitable material specifications, tolerances, and manufacturing process to meet those requirements.

02

Product Sourcing

Our team of dedicated and highly proficient engineers will source a readily available product from a suitable manufacturer that is producing a product which meets the above requirements and parameters.

03

Branding Elements Analysis

Our team will work with our client to identify the private branding requirements, while working with the manufacturer to identify the feasible private branding aspects of the product, including the color, dimensions, and placement location of the branding elements, as well as methods of representing and applying the branding elements, such as silkscreen printing, laser etch, or via a logo patch, and then provide feedback and executable options to our clients accordingly.

04

Design Optimization

Our team will also work with our client and the manufacturer to identify opportunities and executable options for modifications to optimize the fitment and function of the product, to further achieve differentiation and uniqueness.

05

Packaging Analysis

We will also work with our client to identify the private brand packaging requirements, and source the packaging accordingly, while ensuring that the packaging requirements are correctly executed by the manufacturer and the packaging supplier.

06

Track and Monitor

During the production process, our team will continue to manage the production schedule and delivery timeline, track and monitor manufacturing progress, trouble-shoot and resolve any issues that may cause potential delays to maintain momentum, and through our methodical sample approval process, ensure that private branding and packaging requirements are correctly and accurately executed by the manufacturer.

Supply Chain & Purchase Order Management

Consistent and on time delivery when importing products that are manufactured overseas are vital to ensuring a smooth business flow from import to distribution, while balancing and maintaining the optimal level of inventory to ensure that distribution channels are well supplied. This can be achieved through effective management of manufacturers and purchase orders.

Our dedicated team consisting of customer service account executives and operation specialists will work with our clients and our manufacturers to efficiently and effectively administrate, track, and monitor purchase orders, and the corresponding production and shipment schedules, while managing relationships with our manufacturers to foster trust and support.

Our methodical purchase order management process ensures alignment between our clients and our manufacturers on manufacturing lead-time, quality, and ship dates, while keeping our clients well informed on the current status and progress of their purchase orders.

Quality Control & Assurance

Quality is the essence of the product, and the soul of the brand.

Our dedicated and highly proficient quality engineer oversees the implementation of our quality assurance policy in all aspects of product development, product sourcing, and production, to ensure that the quality of the product meets our client’s expectations, while mitigating potential quality issues.

01

Manufacturer Evaluation

We routinely visit manufacturers to evaluate their capability and quality standard, taking into consideration the environment and condition of their production facility and equipment, warehousing of raw materials, R&D and production capacity, and their standardized procedures for production, quality assurance, and quality control, as well as certifications they have achieved, such as ISO-9001 or IATF-16949.

02

Factory Audit Service

As we are already familiar with factory auditing requirements, upon request by the client, we are fully capable of providing in-depth factory audit service, which is executed based on the client’s requirements as well as our own evaluation process, to ensure that the manufacturer meets the client’s standard.

03

Sample Validation Process

Through defining product specifications and our methodical sample approval process, we ensure that the expectation on quality is aligned and in agreement between our clients and our manufacturers.

04

Customized QC Protocols

A unique and innovative product often requires customized protocol for testing, inspection, and quality control, to ensure that the production units are in correct compliance with product specifications. We will work with our clients and our manufacturers to jointly develop and implement the necessary protocols and guidelines for proper testing and inspection to verify product specification compliance.

05

Third Party Laboratory Testing

We can also facilitate any necessary third-party laboratory testing to verify the quality, performance, or safety standard compliance of the material as well as the finished product.

06

Onsite QC Inspection

During production, we can further visit the manufacturer to conduct quality inspections onsite, to ensure that quality control is being consistently executed by the manufacturer.

Shipment Consolidation & Logistics Coordination

Upon completion of production on a Purchase Order, with inspection report approved by our quality engineer, our team of logistics specialists will work with your appointed freight forwarder to expediently ship out the Production Units. In the event that production for multiple Purchase Orders with the same manufacturer are being completed within a similar timeframe, we will also explore options for shipment consolidation to optimize the cost-effectiveness of the shipment.

Our team of operations and logistics specialists will also work together to track and monitor the progress of the shipment, and communicate effectively to keep our clients informed and updated, while ensuring Shipping Documents such as Commercial Invoice, Packing List, and Bill of Lading are issued and provided to our clients accurately and timely.